The World's Largest 3D Printer

The machine, unveiled Tuesday at the University of Maine, is four times larger than the first, ordered less than five years ago, and is capable of printing ever-larger objects. That includes scaling up its 3D-printed home technology using bio-based materials to demonstrate how printed neighborhoods can offer an affordable housing option to tackle homelessness in the region.

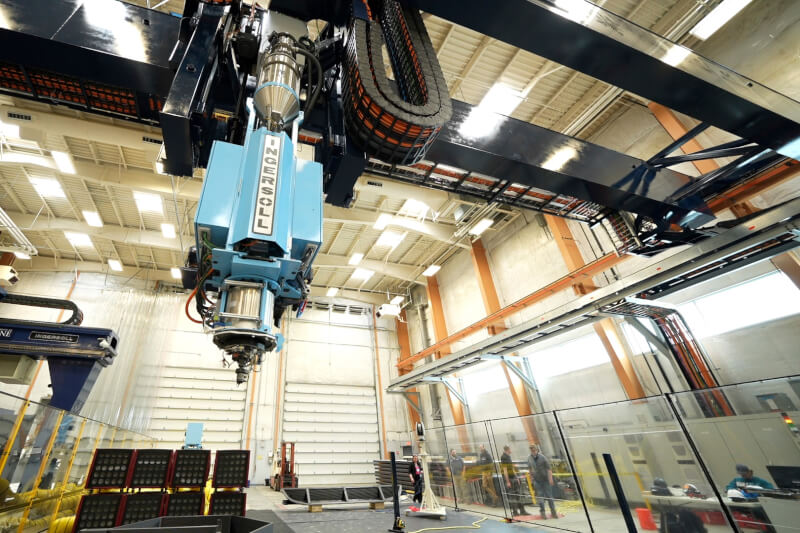

Thermoplastic polymers are pressed out of a printer called the "Factory of the Future 1.0," said Habib Dagher, director of UMaine's Advanced Structures & Composites Center, where both current printers are located. It combines robotic operations with new sensors, high-performance computing and artificial intelligence, Dagher said.

And there could be even bigger printers in the future after the University of Maine breaks ground on a new building this summer.

"We learn from this to design the next one," he said.

The printer frame fills the large building where it is located on the UMaine campus and can print objects measuring 29 meters x 10 meters x 5.5 meters.

It has a voracious appetite and consumes up to 227 kilograms of material per hour.

The original printer, inaugurated in 2019, was certified by Guinness World Records as the world's largest polymer 3D printer, the university said. It was used to create a 600-square-foot, single-family home made from wood fiber and bio-resin materials that can be recycled. Called "BioHome3D," it demonstrated an ability to quickly produce homes. To meet the growing demand for housing, Maine alone will need an additional 80,000 units over the next six years, according to MaineHousing.

Dagher said there is a shortage of both affordable housing and labor to build homes. The university will show how homes can be built almost entirely by a printer with a lower carbon footprint. The building and construction sector accounts for approx. 37% of global greenhouse gas emissions, mainly due to the production and use of materials such as cement, steel and aluminum that have a significant carbon footprint, according to the United Nations Environment Programme.

Such printed buildings can be reused, which is unique compared to current construction. "You can basically break it down, you can paint it if you want, 3D printed parts, and print with them again, do it again," Dagher said before the event.

The Army Corps of Engineers provided most of the funding for the new multimillion-dollar printer, said Dannel Malloy, chancellor of the University of Maine System. It was built by the university in partnership with Ingersoll Rand for the construction of the printer and Somatex for the supporting structure, the officials said.

In the future, the researchers plan to experiment with the material the machine consumes, including more bio-based raw materials from wood scraps abundant in Maine, America's most forested state.

But it can be used for a number of other creations and has already been used for various things, from boats to Department of Defense structures. The university previously displayed a 25-foot boat created by the first printer. Upcoming projects with the new printer include a 50-foot boat and housing for the homeless, Dagher said.

Latest printer

-

10 Octprinter

-

02 Octprinter

Bambu Lab opens Flagship Store in China

-

25 Junprinter

Elegoo launches reinforced filament

-

20 Junprinter

Bambu Lab Store turns three years old

-

25 Marprinter

Bambu Lab launches H2D

-

03 Marprinter

The world's first flying 3D printer

-

14 Febprinter

BIQU Panda BuildPlate CryoGrip

-

22 Janprinter

Elegoo Saturn 4 Ultra 16K

Most read printer

Latest printer

-

10 Octprinter

New arrivals from Bambu Lab

-

02 Octprinter

Bambu Lab opens Flagship Store in China

-

25 Junprinter

Elegoo launches reinforced filament

-

20 Junprinter

Bambu Lab Store turns three years old

-

25 Marprinter

Bambu Lab launches H2D

-

03 Marprinter

The world's first flying 3D printer

-

14 Febprinter

BIQU Panda BuildPlate CryoGrip

-

22 Janprinter

Elegoo Saturn 4 Ultra 16K