Bambu Lab unveils P2S

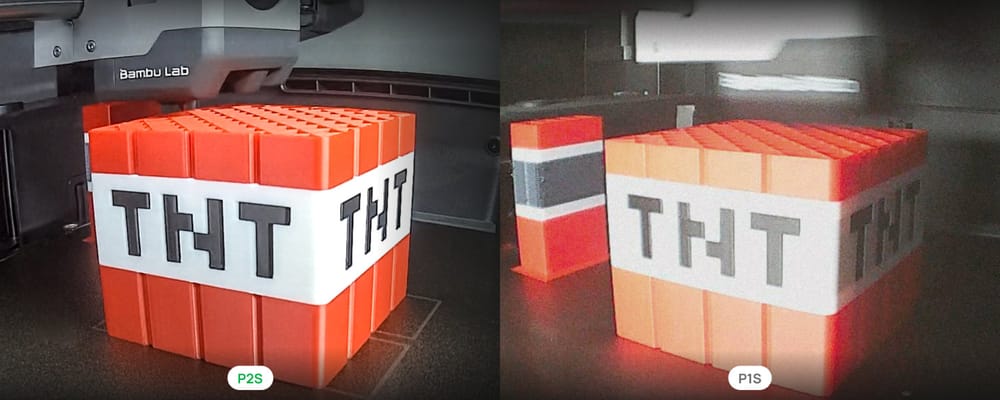

Under the title "The Icon Redefined", Bambu Lab has presented their P2S 3D Printer. Since its launch two and a half years ago, the P series has been the biggest sales success for Bambu Lab, so it makes sense that they are updating the series with new features. In short, it is an upgrade of the P1 printer, which now gets a lot of the smart tech that we have previously seen in Bambu Lab's more expensive H series of 3D Printers.

Although P2S still retains the P name, Bambu Lab says they have redesigned it from the ground up, so it now comes with a number of features that make it easier to use and more reliable.

The list of upgrades on the new Bambu Lab P2S is impressive and includes:

2nd generation user interface on 5-inch touchscreen

The P2S comes with a fully upgraded touchscreen and a powerful processor running Bambu Labs’ 2nd generation intuitive user interface. It offers smoother interactions, improved graphics and clear step-by-step instructions. Simple, intuitive and easy to use, even for beginners.

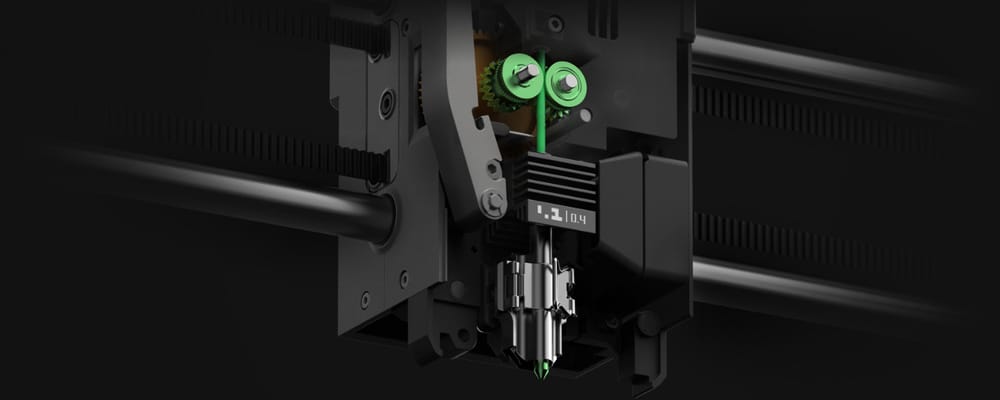

PMSM servo extruder

The PMSM servo extruder delivers up to 8.5 kg of maximum extrusion force, 70% more than its predecessor, significantly improving stability at high flow rates. The new servo architecture senses resistance and position at 20 kHz and actively detects filament wear and clogs in real time.

Automatic calibration of flow dynamics

P2S uses a high-resolution, high-frequency eddy current sensor to calibrate the flow dynamics. Intelligent algorithms actively adjust the flow rate based on the measurements, ensuring precise and consistent extrusion in every layer and corner.

Adaptive air cooling

The Adaptive Airflow System draws cool air directly from the outside, significantly improving cooling efficiency. This allows you to print low-temperature filaments with the doors closed, without compromising overhang quality or risking nozzle clogging.

Adaptive heat preservation of air flow

A flap-controlled Adaptive Airflow System effectively retains heat inside the chamber, while filtering internal air through a high-performance carbon filter. This allows for the use of more demanding filament types while keeping the air quality in the work area clean and safe.

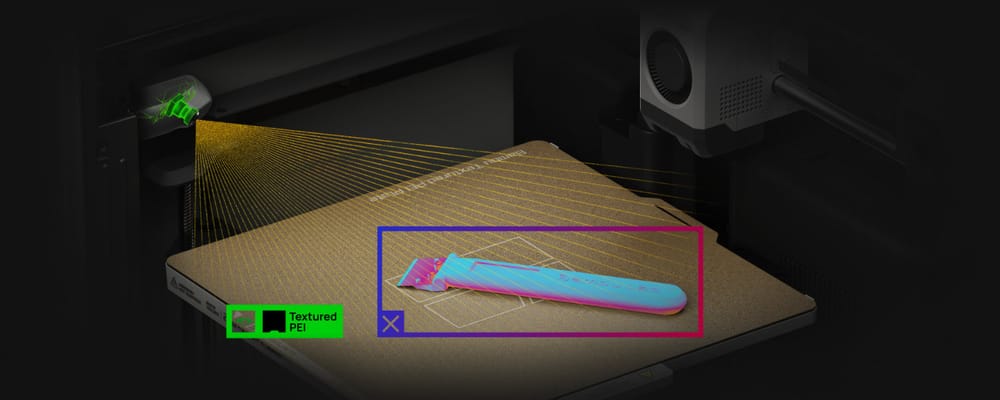

AI error detection

P2S introduces advanced AI-powered image recognition that actively detects common printing issues such as “spaghetti, nozzle blobs and air printing”. It also cross-checks build plate and nozzle type with slicer settings to ensure a safe and accurate start to every print.

1080P live view with high refresh rate

Improved LED lighting significantly increases the clarity of live video and time-lapse footage. Together with a high-frame-rate camera, users can easily monitor the printer remotely and capture beautiful time-lapse videos for sharing on social media.

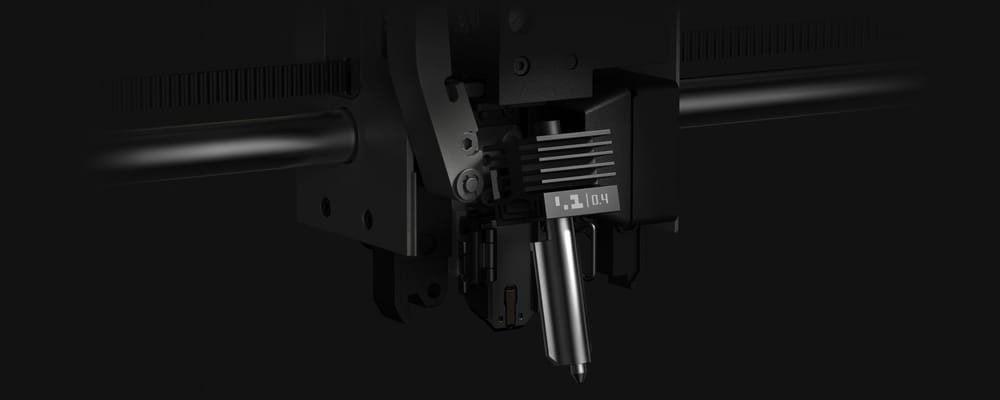

Quick-Swap hotend

The P2S features a Quick-Swap hotend design with a simple one-clip mechanism that releases the entire nozzle and heatsink, completely eliminating the need for cable connections.

AMS 2 Pro

The P2S Combo comes standard with the reliable multi-color AMS 2 Pro system, which features improved filament drying. A groundbreaking active ventilation system dries filament 30% faster than sealed heating and maintains low humidity for better storage and print quality.

Other specifications:

- Construction volume: 256 × 256 × 256 mm

- Maximum nozzle temperature: 300°C

- Standard nozzle: 0.4mm (also supports 0.2/0.6/0.8mm)

- Built-in filament cutter

- Maximum hotplate temperature: 110°C

Sensors:

- Door sensor

- Filament end detection

- Filament filters/clogging sensor

- Filament odometry

- Power outage recovery

The new Bambu Lab P2S will arrive in November and is listed with a price (before shipping) of just under 5600 kroner for a Combi version with the new AMS 2 Pro or just under 3900 kroner for the printer alone.

As a practical note, Bambu Lab has also emphasized that the launch of P2S does not mean that P1S is being taken off the market. The intention is to continue to sell and support that series going forward.

Latest printer

-

15 Octprinter

-

10 Octprinter

New arrivals from Bambu Lab

-

02 Octprinter

Bambu Lab opens Flagship Store in China

-

25 Junprinter

Elegoo launches reinforced filament

-

20 Junprinter

Bambu Lab Store turns three years old

-

25 Marprinter

Bambu Lab launches H2D

-

03 Marprinter

The world's first flying 3D printer

-

14 Febprinter

BIQU Panda BuildPlate CryoGrip

Most read printer

Latest printer

-

15 Octprinter

Bambu Lab unveils P2S

-

10 Octprinter

New arrivals from Bambu Lab

-

02 Octprinter

Bambu Lab opens Flagship Store in China

-

25 Junprinter

Elegoo launches reinforced filament

-

20 Junprinter

Bambu Lab Store turns three years old

-

25 Marprinter

Bambu Lab launches H2D

-

03 Marprinter

The world's first flying 3D printer

-

14 Febprinter

BIQU Panda BuildPlate CryoGrip